ZoneStar Z9V5Pro

- Core XY

- 4 to 1 mixing/non-mixing hot-ends

- 300x300x400 mm (actual bed 310x310mm)

- STM32 based board

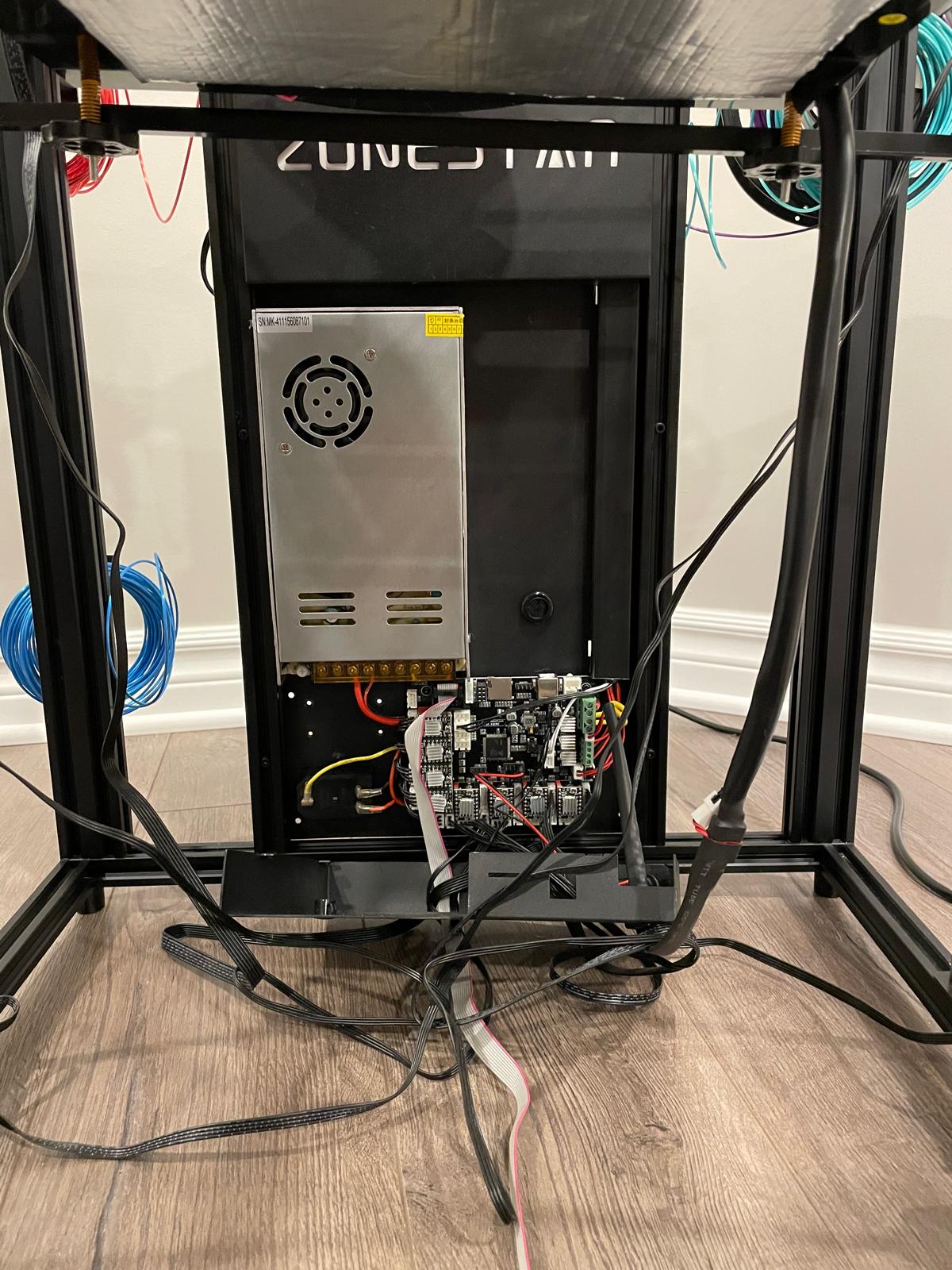

Printer internals overview

The covers are hold by 4 screws each:

- Top contains stepper motors of extruders and connectors to printing head:

- Bottom contains the main board:

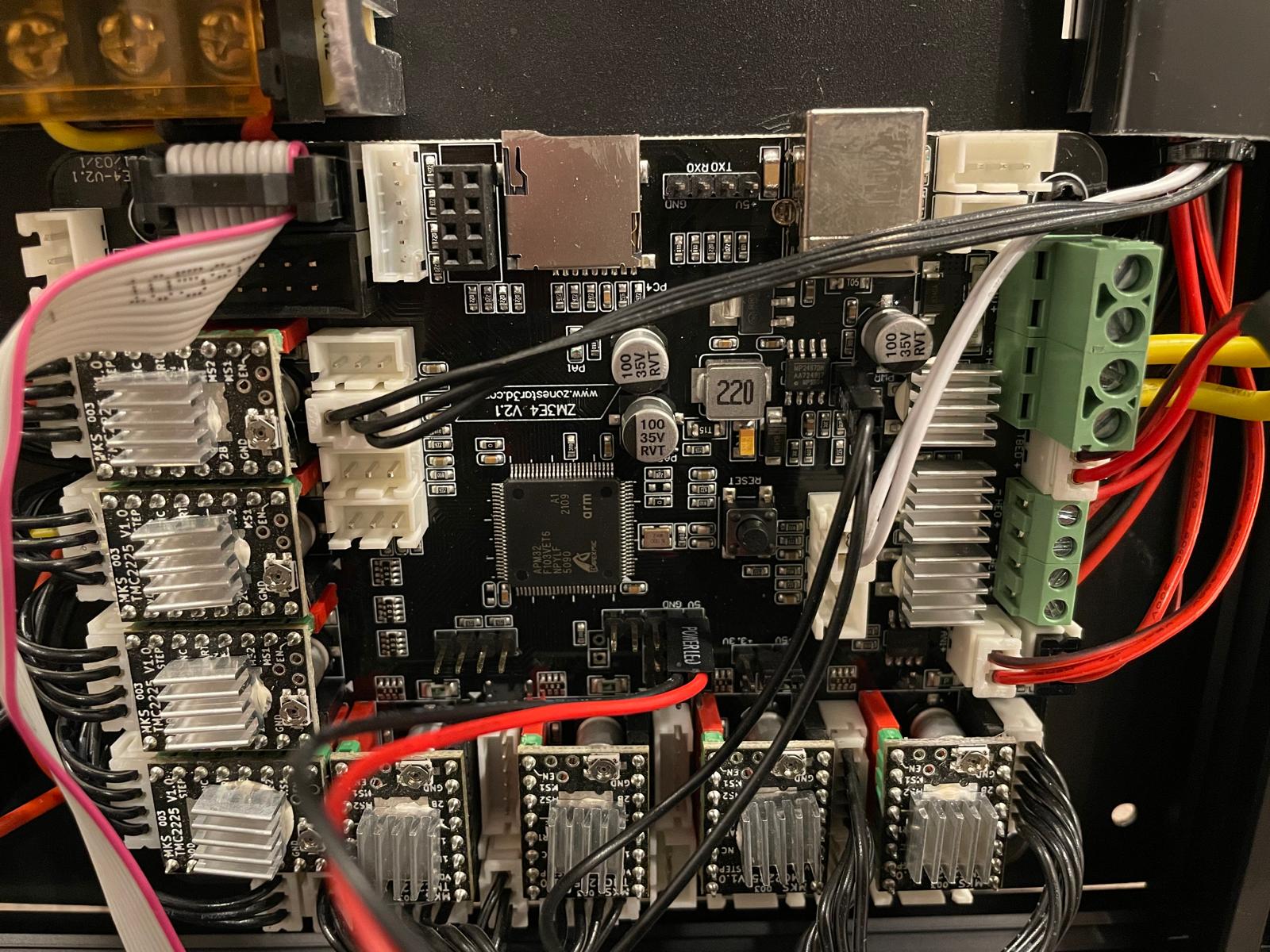

The board is ZM3E4 V2.1:

- Schematics and parts placement were found in Zonestar3D GitHub

- In schematics, it is

STM32F103VCT6, but on board, it is cloneAPM32 F103VET6by Geehy

Klipperize Z9V5Pro-MK4 (with non mixing E4 hotend)

Found references

- Forked from: Z9V5Pro-MK4-Klipper

- In addition, found this: Z9V5-mixing-klipper

- My dynamically updated profile

Klipper Flashing procedure

- Obtain Klipper by clonning it: klipper3D

- Configure by going to cloned folder in terminal and run

make menuconfigin menu choose:

- MCU Architecture - STM32

- Processor model - STM32F103

- Bootloader offset - 20KiB bootloader

- Communication interface (USB(on PA11/PA12)) and press

QandYto save and exit

- Build FW file by running:

makeit should complete without errors (otherwise install dependencies till it works). You will get

klipper.binin./out/folder. - Prepairing uSD-Card:

- Copy the

klipper.binto root of uSD-Card and rename it tofirmware.bin - remove

old_fw.binif exists - Unmount (eject) uSD-Card to cause

fsync

- Copy the

- Flashing printer:

- Power off power supply (PSU) of the printer

- Insert uSD-Card

- Power on PSU

- Press and hold for few sec small power button on bottom main board cover (the Zonestar logo might blink few times but will stay dark after it).

In my case, the printer wasn’t found and power cycle didn’t help. Looking on Linux logs using journalctl -f showed that it had USB detection errors and it was solved by eliminating USB-hub and plugging-in printer directly into PC: Errors via hub:

Nov 02 02:44:20 pc-name kernel: usb 1-10.4: new low-speed USB device number 71 using xhci_hcd

Nov 02 02:44:20 pc-name kernel: usb 1-10.4: device descriptor read/64, error -32

Nov 02 02:44:20 pc-name kernel: usb 1-10.4: device descriptor read/64, error -32

Nov 02 02:44:21 pc-name kernel: usb 1-10.4: new low-speed USB device number 72 using xhci_hcd

Nov 02 02:44:21 pc-name kernel: usb 1-10.4: device descriptor read/64, error -32

Nov 02 02:44:21 pc-name kernel: usb 1-10.4: device descriptor read/64, error -32

Nov 02 02:44:21 pc-name kernel: usb 1-10-port4: attempt power cycle

Direct connection:

Nov 02 02:45:18 pc-name kernel: usb 1-8: new full-speed USB device number 77 using xhci_hcd

Nov 02 02:45:18 pc-name kernel: usb 1-8: New USB device found, idVendor=1d50, idProduct=614e, bcdDevice= 1.00

Nov 02 02:45:18 pc-name kernel: usb 1-8: New USB device strings: Mfr=1, Product=2, SerialNumber=3

Nov 02 02:45:18 pc-name kernel: usb 1-8: Product: stm32f103xe

Nov 02 02:45:18 pc-name kernel: usb 1-8: Manufacturer: Klipper

Nov 02 02:45:18 pc-name kernel: usb 1-8: SerialNumber: 28001100170000464C59504E

Nov 02 02:45:18 pc-name mtp-probe[732041]: checking bus 1, device 77: "/sys/devices/pci0000:00/0000:00:14.0/usb1/1-8"

Nov 02 02:45:18 pc-name kernel: cdc_acm 1-8:1.0: ttyACM0: USB ACM device

Nov 02 02:45:18 pc-name mtp-probe[732041]: bus: 1, device: 77 was not an MTP device

Nov 02 02:45:18 pc-name snapd[2187845]: hotplug.go:200: hotplug device add event ignored, enable experimental.hotplug

Nov 02 02:45:18 pc-name mtp-probe[732048]: checking bus 1, device 77: "/sys/devices/pci0000:00/0000:00:14.0/usb1/1-8"

Nov 02 02:45:18 pc-name mtp-probe[732048]: bus: 1, device: 77 was not an MTP device

Changes from forked

- Z-sensor wasn’t mapped so added:

[probe] pin: !PB13 ... - Fixed bed dimensions

- due to wiring Y axis getting stuck into motor connector and so Y movement limited by 300mm (bed is 310mm)

- screw locations also fixed and added delta of z-sensor position (for some reason it doesn’t get compensated automatically)

- Calibrated

rotation_distancefor all 4 extruders

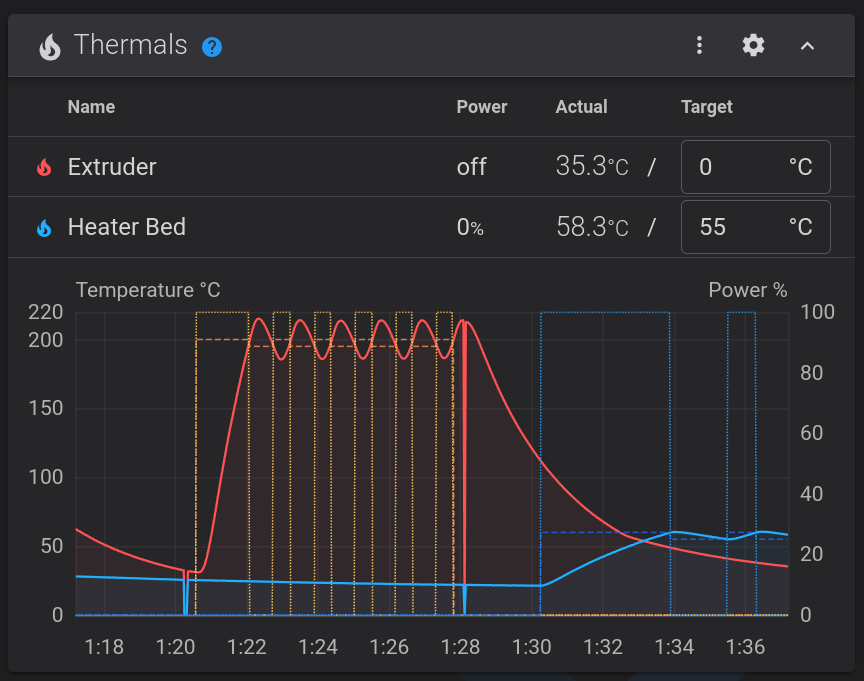

Heaters PID calibrations

To calibrate both PID loops of heaters used:

PID_CALIBRATE HEATER=extruder TARGET=200

SAVE_CONFIG

restart

PID_CALIBRATE HEATER=heater_bed TARGET=60

SAVE_CONFIG

restart

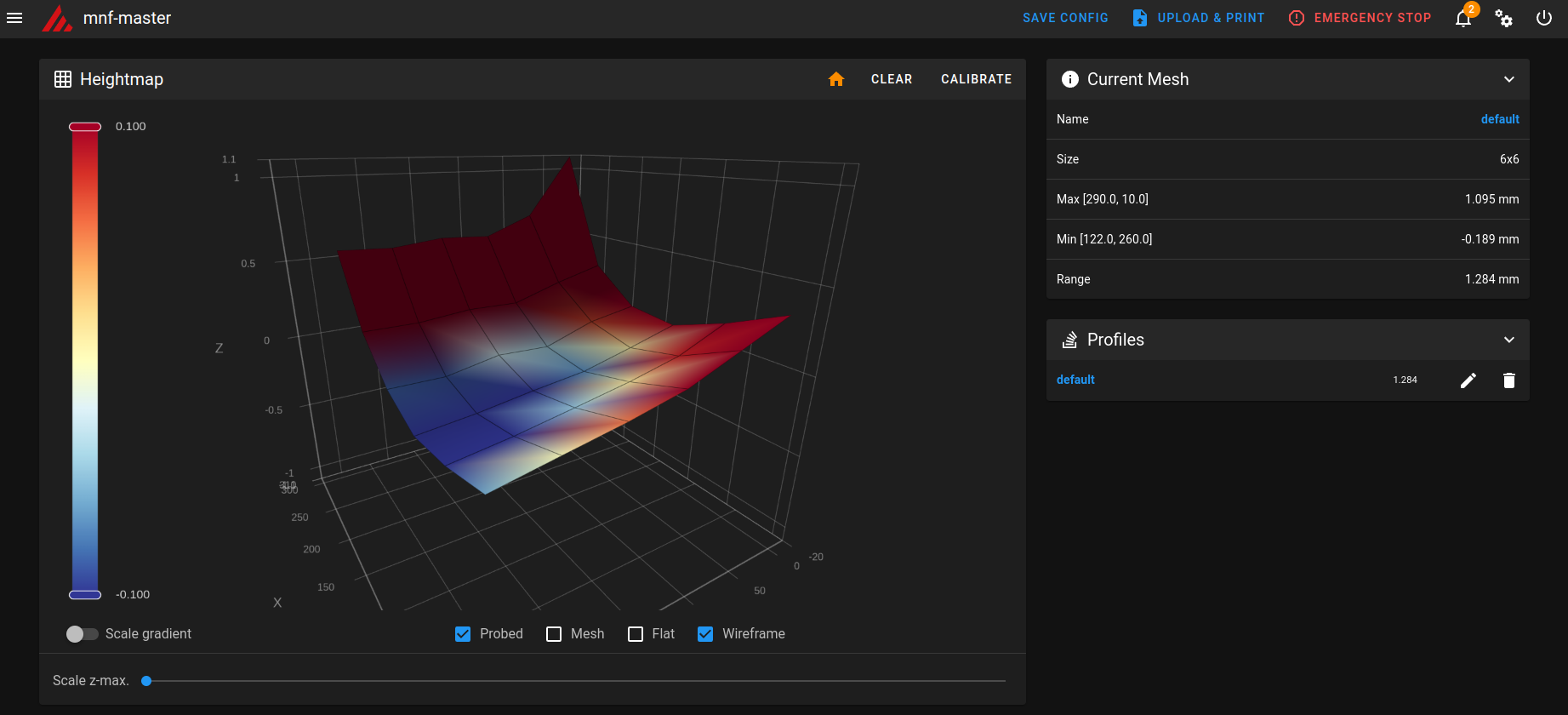

Bed Mesh

Created initial bed mesh before fixing anything using GUI HEIGHTMAP clicking CALIBRATE and then running SAVE_CONFIG in console result:

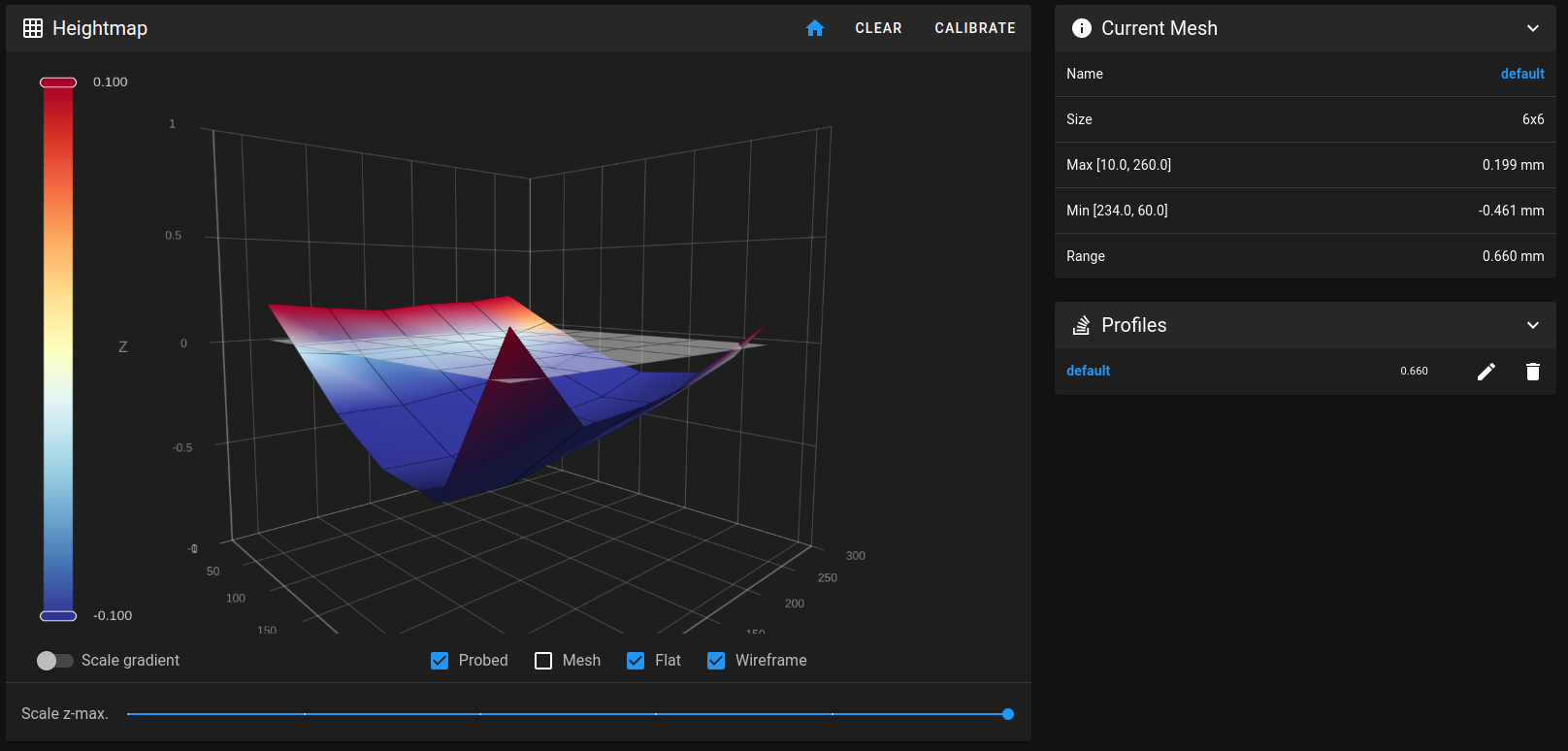

After that used

SCREWS_TILT_CALCULATE

to adjust screws and bring all corner to the same plane, and running mesh again:

Interestingly, I added plastic rectangle below PEI flexible top and the mesh didn’t change, then added metallic ruler and the sensor was triggered even before going down. It means, that the sensor measures metal plate/magnetic sticker and not real bed position. Hopefully, switching to steel PEI plate will solve the issue. Another option is to switch to BLTouch sensor that uses mechanical contact instead of inductive proximity sensor.

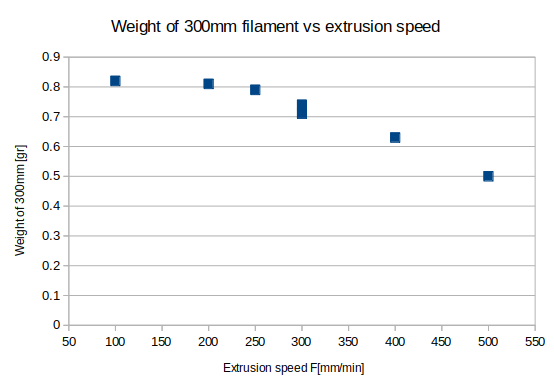

Extrusion speed

Repeating experiment from this video:

https://www.youtube.com/watch?v=0xRtypDjNvI

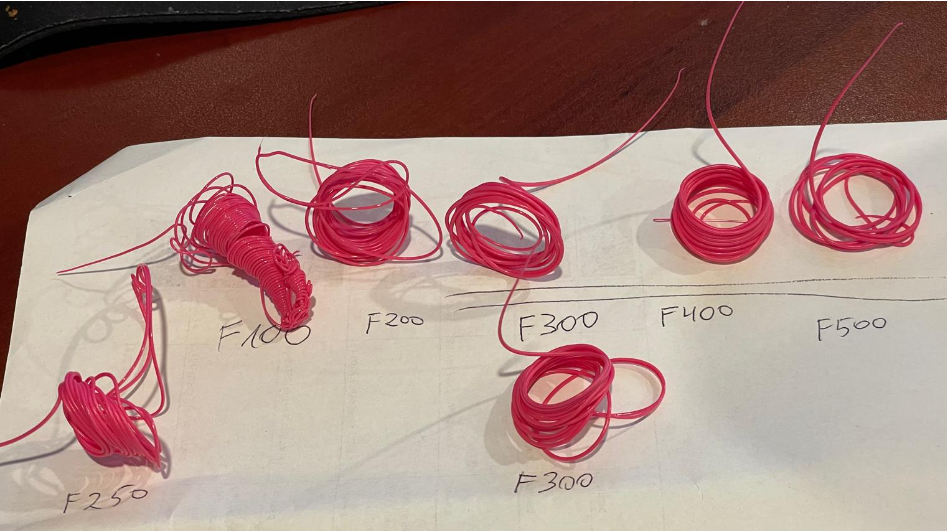

| F [mm/min] | E300mm [gr] |

|---|---|

| 100 | 0.82 |

| 200 | 0.81 |

| 250 | 0.79 |

| 300 | 0.74 |

| 300 | 0.71 |

| 400 | 0.63 |

| 500 | 0.5 |

So it seems that printing above F200 starts extrude less material.

The 200mm/min of 1.75mm filament is equal 8.0176 mm^3/s

200/60*(1.75/2)^2*pi = 8.0176 mm^3/s

Later tried to increase tension between gears and filament using adjustment screw and the results:

| F [mm/min] | E300mm [gr] |

|---|---|

| 300 | 0.79 |

| 400 | 0.70 |

So 300mm/min seems ok:

300/60*(1.75/2)^2*pi = 12.026 mm^3/s

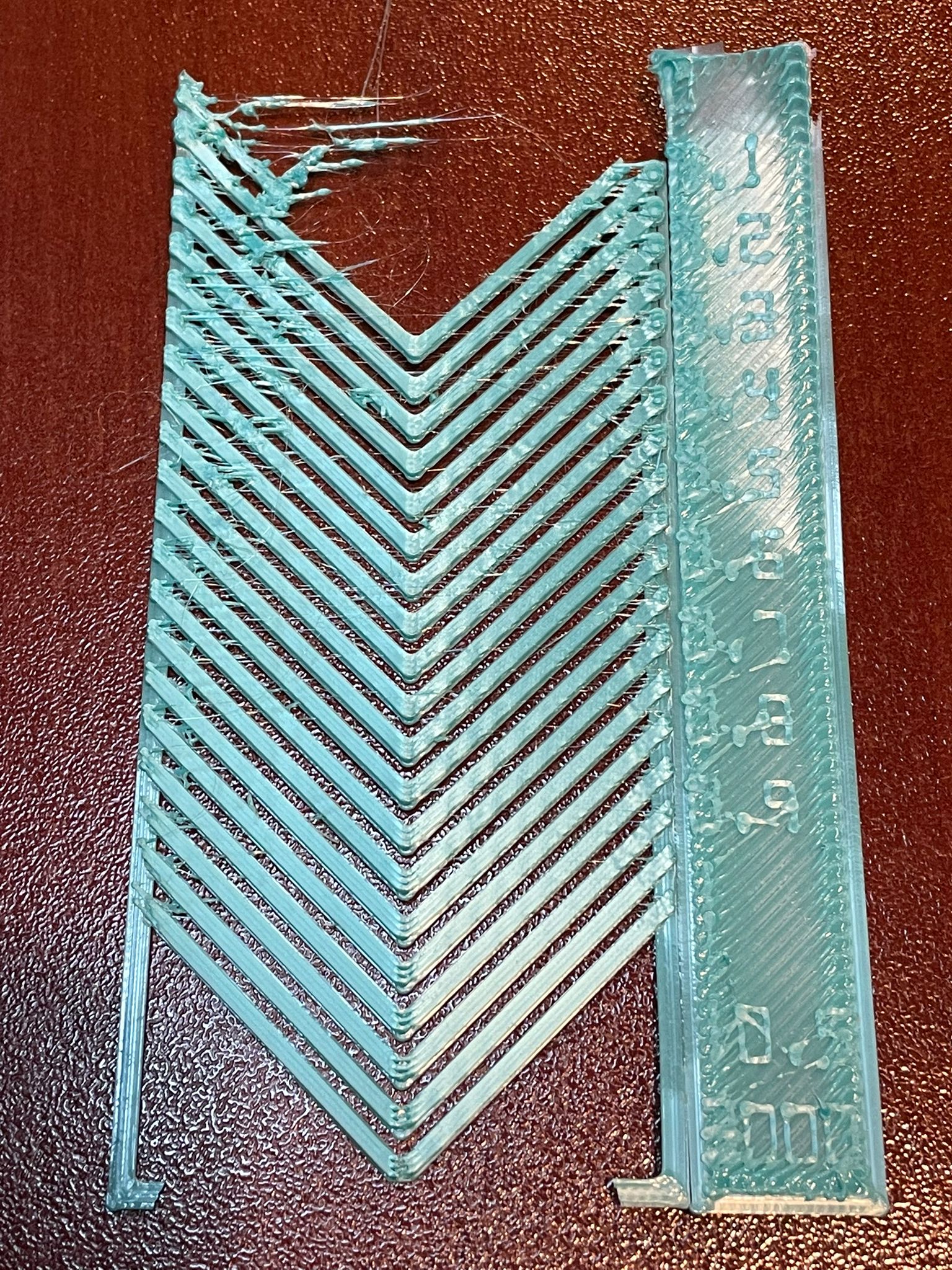

Pressure Advance (PA) calibrations

Uses to start pushing fillament a little before starting printing and stopping extruding a little earlier, to compensate for long Bowden tubing that connects extruder and printing head and gives slack for filament to move and compress like spring inside tubing.

Using Orca slicer’s Calibrations menu created PA pattern for Bowden printers:

Looking at the corners, at 0.6 it looks sharp and the under-extrusion just starts.

The value was put into config and into slicer settings.

[extruder]

...

pressure_advance = 0.6

...

After configuring this I started to get Klipper errors of MCU 'mcu' shutdown: Stepper too far in past. Few evening past, I understood that it happens at short intervals and interplays between feed rate (F) and PA values. Still, didn’t solve it completely.

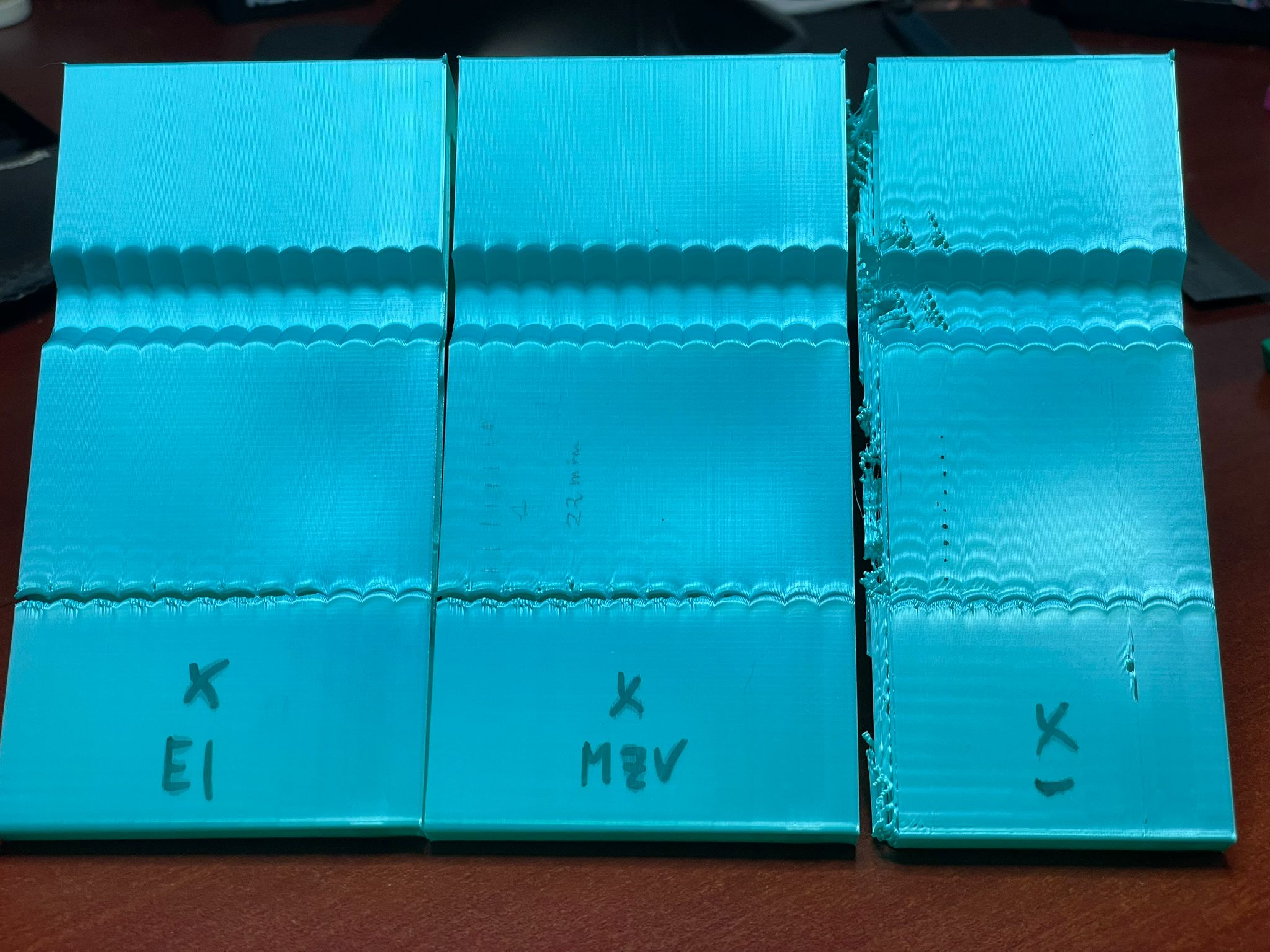

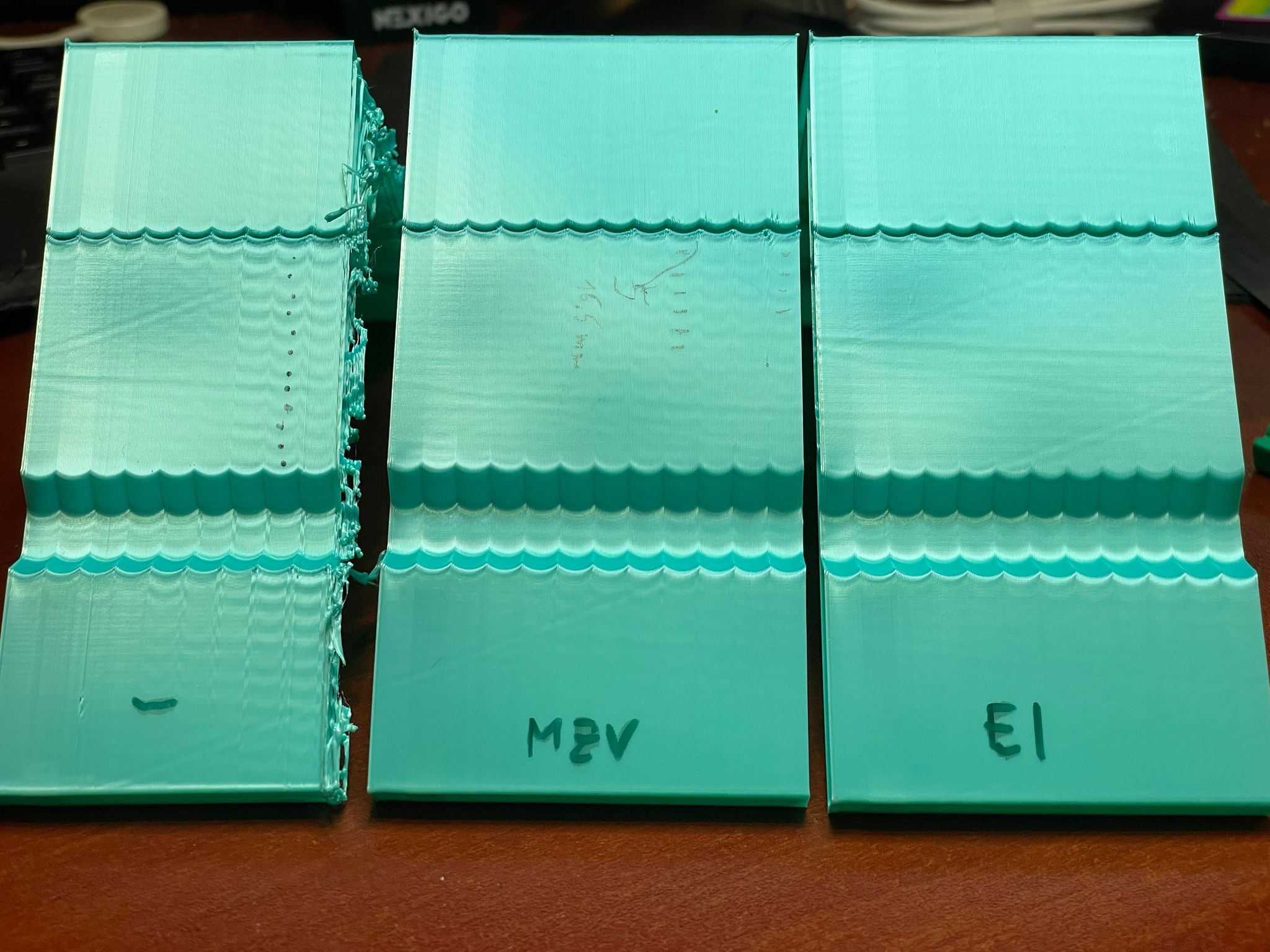

Input Shaper

Used to modify frequency of pulses provided to motors to avoid generating oscillations due to mechanical resonances in printer construction.

Calibrated accordingly to Klipper manual

My initial prints and comparison of 2 methods EI and MZV. Haven’t learned them yet, but sticked to recommendation to use MZV as less smoothing.

3 prints:

-- no input shaping, starting accel=1000, step 500MZV- starting accel=500, step 1000EI- starting accel=500, step 1000

X axis:

Y axis:

Initial input shaper print failed because vibrations and probably bad cleaning of printer head before print. Solved by enabling skirt in slicer and so few loops of filament are extruded around model and so all leakages are wiped off before starting.

Retraction

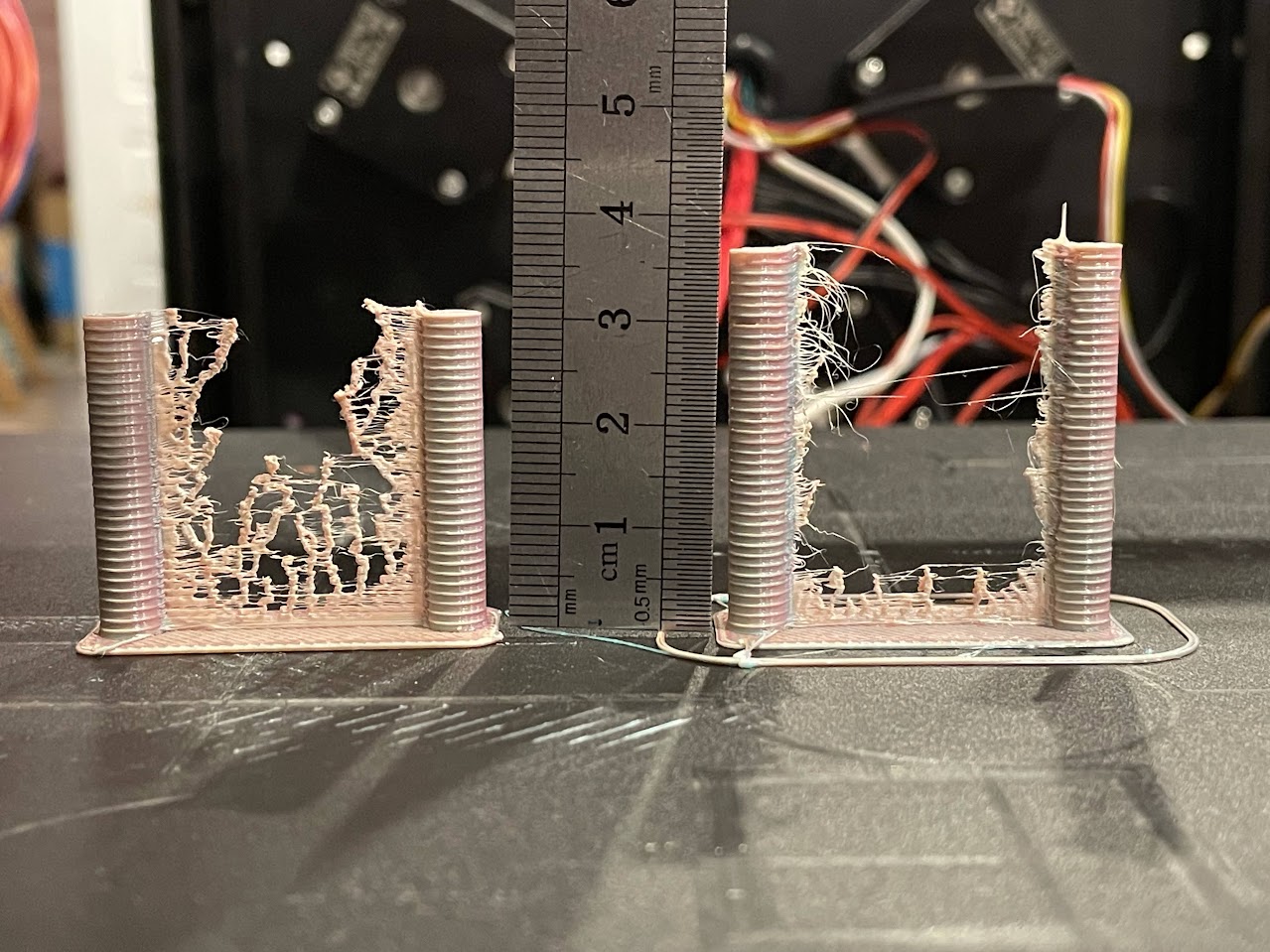

I run retraction calibration of mix of 4 to 1 with equal ratios 25%/25%/25%/25%:

The left tower is 0.5mm/mm from h=0 to 30mm, providing retraction values from r=0 to 15mm and given mix ratios 0f 25% it means each color was retracted at the peak by 15/4=3.75mm (while recommended is 5..8mm) and as seen from results for all values the head was oozing heavily.

The right tower, is 1mm/mm from r=12mm retraction at h=0mm to r=48mm at h=36mm.

As seen from the left tower, the retraction of 3.75mm is not enough. From the right, the optimum is probably somewhere between h=6 to 10mm so r=18 to 22mm, choosing 20mm give that each filament was retracted by 20*0.25=5mm.

The problem that depending on mixing ratio, the filaments will be retracted by default distances. To solve it I created macros for FW retraction G10/G11, that ignore mixing factors and retract by hardcoded 5mm value.

During testing ti gave better results, but running longer print, the filaments that are not participating in mixing, retracted back and forth at the same point and extruder’s gear cuts into it and breaks the filament.

The solution was modifying macros one more time retracting only active filaments: (I added to M164 to store also normalized mixed factors and so very small values mean these filaments are not active)

[gcode_macro M164]

description: Applies the set mixing factors to the extruders

# default values:

variable_e0_parts : 100

variable_e1_parts : 0

variable_e2_parts : 0

variable_e3_parts : 0

variable_e0_norm : 0

variable_e1_norm : 0

variable_e2_norm : 0

variable_e3_norm : 0

gcode:

# normalize the parts to sum of 1

SET_GCODE_VARIABLE MACRO=M164 VARIABLE=e0_norm VALUE={e0_parts / (e0_parts + e1_parts + e2_parts + e3_parts) | float}

SET_GCODE_VARIABLE MACRO=M164 VARIABLE=e1_norm VALUE={e1_parts / (e0_parts + e1_parts + e2_parts + e3_parts) | float}

SET_GCODE_VARIABLE MACRO=M164 VARIABLE=e2_norm VALUE={e2_parts / (e0_parts + e1_parts + e2_parts + e3_parts) | float}

SET_GCODE_VARIABLE MACRO=M164 VARIABLE=e3_norm VALUE={e3_parts / (e0_parts + e1_parts + e2_parts + e3_parts) | float}

M118 scaled rot-dist_e0 { printer.configfile.settings.extruder.rotation_distance / (e0_norm + 0.000001) | float }

M118 scaled rot-dist_e1 { printer.configfile.settings['extruder_stepper extruder_1'].rotation_distance / (e1_norm + 0.000001) | float }

M118 scaled rot-dist_e2 { printer.configfile.settings['extruder_stepper extruder_2'].rotation_distance / (e2_norm + 0.000001) |float }

M118 scaled rot-dist_e3 { printer.configfile.settings['extruder_stepper extruder_3'].rotation_distance / (e3_norm + 0.000001) |float }

# activate stepper percentages

SYNC_EXTRUDER_MOTION EXTRUDER=extruder MOTION_QUEUE=extruder

SYNC_EXTRUDER_MOTION EXTRUDER=extruder_1 MOTION_QUEUE=extruder

SYNC_EXTRUDER_MOTION EXTRUDER=extruder_2 MOTION_QUEUE=extruder

SYNC_EXTRUDER_MOTION EXTRUDER=extruder_3 MOTION_QUEUE=extruder

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder DISTANCE={ printer.configfile.settings.extruder.rotation_distance / (e0_norm+0.000001)|float }

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_1 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_1'].rotation_distance / (e1_norm+0.000001)|float }

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_2 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_2'].rotation_distance / (e2_norm+0.000001)|float }

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_3 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_3'].rotation_distance / (e3_norm+0.000001)|float }

M118 Mixing factors {e0} {e1} {e2} {e3} are activated

[gcode_macro G10]

description: performs retraction and temporary cancels mixing factors but only on active extruders e_norm < 0.001

# default values:

variable_retraction_distance : 5

variable_feedrate: 40

gcode:

{% set e0_norm = printer["gcode_macro M164"].e0_norm|default(1) %}

{% set e1_norm = printer["gcode_macro M164"].e1_norm|default(0) %}

{% set e2_norm = printer["gcode_macro M164"].e2_norm|default(0) %}

{% set e3_norm = printer["gcode_macro M164"].e3_norm|default(0) %}

# activate stepper percentages

SYNC_EXTRUDER_MOTION EXTRUDER=extruder MOTION_QUEUE=extruder

SYNC_EXTRUDER_MOTION EXTRUDER=extruder_1 MOTION_QUEUE=extruder

SYNC_EXTRUDER_MOTION EXTRUDER=extruder_2 MOTION_QUEUE=extruder

SYNC_EXTRUDER_MOTION EXTRUDER=extruder_3 MOTION_QUEUE=extruder

{% if e0_norm < 0.001 %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder DISTANCE={ printer.configfile.settings.extruder.rotation_distance / (e0_norm+0.000001) | float }

{% else %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder DISTANCE={ printer.configfile.settings.extruder.rotation_distance | float }

{% endif %}

{% if e1_norm < 0.001 %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_1 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_1'].rotation_distance / (e1_norm+0.000001) | float }

{% else %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_1 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_1'].rotation_distance | float }

{% endif %}

{% if e2_norm < 0.001 %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_2 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_2'].rotation_distance / (e2_norm+0.000001) | float }

{% else %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_2 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_2'].rotation_distance | float }

{% endif %}

{% if e3_norm < 0.001 %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_3 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_3'].rotation_distance / (e3_norm+0.000001) | float }

{% else %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_3 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_3'].rotation_distance | float }

{% endif %}

M118 Retracting all active extruders by {retraction_distance} mm

G1 E-{retraction_distance} F{feedrate*60 | float}

[gcode_macro G11]

description: performs unretraction and sets back mixing factors

# default values:

variable_unretraction_distance : 5

variable_feedrate: 40

gcode:

{% set e0_norm = printer["gcode_macro M164"].e0_norm|default(1) %}

{% set e1_norm = printer["gcode_macro M164"].e1_norm|default(0) %}

{% set e2_norm = printer["gcode_macro M164"].e2_norm|default(0) %}

{% set e3_norm = printer["gcode_macro M164"].e3_norm|default(0) %}

# activate stepper percentages

SYNC_EXTRUDER_MOTION EXTRUDER=extruder MOTION_QUEUE=extruder

SYNC_EXTRUDER_MOTION EXTRUDER=extruder_1 MOTION_QUEUE=extruder

SYNC_EXTRUDER_MOTION EXTRUDER=extruder_2 MOTION_QUEUE=extruder

SYNC_EXTRUDER_MOTION EXTRUDER=extruder_3 MOTION_QUEUE=extruder

{% if e0_norm < 0.001 %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder DISTANCE={ printer.configfile.settings.extruder.rotation_distance / (e0_norm+0.000001) | float }

{% else %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder DISTANCE={ printer.configfile.settings.extruder.rotation_distance | float }

{% endif %}

{% if e1_norm < 0.001 %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_1 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_1'].rotation_distance / (e1_norm+0.000001) | float }

{% else %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_1 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_1'].rotation_distance | float }

{% endif %}

{% if e2_norm < 0.001 %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_2 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_2'].rotation_distance / (e2_norm+0.000001) | float }

{% else %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_2 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_2'].rotation_distance | float }

{% endif %}

{% if e3_norm < 0.001 %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_3 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_3'].rotation_distance / (e3_norm+0.000001) | float }

{% else %}

SET_EXTRUDER_ROTATION_DISTANCE EXTRUDER=extruder_3 DISTANCE={ printer.configfile.settings['extruder_stepper extruder_3'].rotation_distance | float }

{% endif %}

M118 Unretracting all active extruders by {unretraction_distance} mm

G1 E{unretraction_distance} F{feedrate*60 | float}

M118 Returning mixing factors

M164

Continue to OrcaSlicer configuration…